Boge Compressors

-

Aftermarket

BOGE service management - comprehensive and reliable

Your decision to use BOGE products for your compressed air supply underscores how demanding your requirements are. BOGE complements its products with comprehensive customer service support - every day, around the clock and as fast as possible. You can rely on our local and global BOGE support teams and spare parts depots for guaranteed dependable and complete availability.In order to ensure optimum functioning of all machines and equipment we have designed a perfectly harmonised performance programme. In addition to the highest product quality, this programme includes the indisputable competence of our technicians and engineers. Regular training and instruction courses are a must for our highly qualified employees. You can count on the professional infrastructure of the BOGE service management. This is true for both small repairs and extensive maintenance works. Don't forget: Preventive maintenance saves costs.BOGE Service Packages: You Can Depend On.

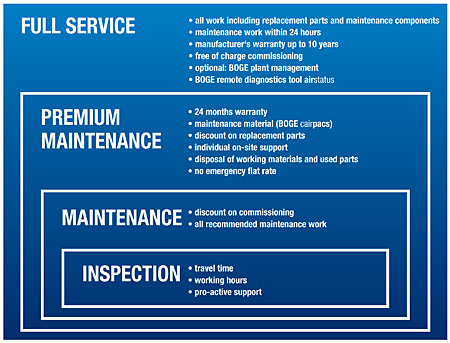

Service that lives up to its name: BOGE service allows you to concentrate one hundred percent on your work. There's no need to keep an eye on when the next inspection for your compressed air station is due. No need either to ensure that regular maintenance is carried out and documented. You can rest assured that there'll be no unexpected costs. All you need to do in fact is: speak to us about your requirements and we will generate a service package to suit your needs.The Principle Behind Our Service: Tailor-made to meet individual requirements. The various service packages largely build on each other. Nearly all features contained in the inspection package are included in the maintenance package. The premium maintenance package, in turn, includes the features of the maintenance package. And finally, the full service package provides the widest range of features. In this way, it is easy for you to achieve the ideal package in every respect. As a rule of thumb: the more comprehensive the service agreement, the more that you, as the compressed air station operator, can rest assured that the safety and functionability of your system is being taken care of for you. FULL SERVICE - FOR MAXIMUM SAFETY AND ASSURANCE

FULL SERVICE - FOR MAXIMUM SAFETY AND ASSURANCE

All work on your compressed air system is included without exception - with guaranteed reaction times. To enhance transparency, we can optionally equip your system with BOGE airstatus. This tool combines four compressed air management tasks in one device: fault indicator, remote data polling, data retention and web visualisation. In the event of a fault, a message is sent to an authorised person in the form of a text message, email, voicemail or fax. You enjoy a completely reliable compressed air supply - at a transparent and foreseeable cost you can budget for in advance.PREMIUM MAINTENANCE - ADDED SUPPORT

Premium maintenance covers all maintenance work including all wear and tear parts as well as all parts to be serviced and including a subsequent maintenance report, with no need for you to worry about the timing and dates. You enjoy a whole 24 months' guarantee for your BOGE compressed air system. For a one-off additional charge we will also include remote monitoring of your system with BOGE airstatus at your request.MAINTENANCE - MANAGEABLE AND FLEXIBLE

We will maintain your compressed air system every 3,000 operating hours, but at least once a year. As an optional feature, our BOGE service technician will also carry out any necessary small repairs straight away. You will receive a maintenance and service checkbook filled in by us which will document the long-term value retention of your machine.INSPECTION - A GOOD BASIS

BOGE's inspection package provides a reliable safety base to set your mind at rest. We will perform an inspection of your compressed air system every three months. You will always be kept up to date on the state of your system and will be able to plan for any upcoming maintenance or repairs in your operating schedule. If maintenance is due, you can select to be billed separately for the option of having this performed either immediately or at a later date.AIReport generates air according to demand

Compressed air stations will only work at their highest efficiency level if the entire system is taken into account and harmonised accordingly. The BOGE AIReport equipment is ideally suited to this end. The AIReport check-up system helps to detect weak points during long term monitoring and to effectively improve compressed air systems on the basis of solid know-how and experience. The crucial parameter of the efficiency of a compressor station is its energy consumption. How much energy is needed per generated or used cubic meter of compressed air? Does the system produce only the exact amount of compressed air that is actually needed?The amount of leakage is an important criterion to determine the efficiency. It should be as small as possible. The same is true for the pressure drop between the compressed air generator and the compressed air user. The highest generated pressure should also be a low as possible in order ensure continued economical operation. Checking for pressure losses in the pipework, leakage detection by means of ultrasonic gauges or monitoring of inefficient idle operation of screw compressors are to be examined without delay - using the AIReport for most effective measurements. Such measurements should be carried out over several production days (approx. 1 week) in order to determine the most efficient operation of the ideal compressor combination - "air according to demand" so to speak. At the same time, additional information is provided on the operation process in your own facility and enabling you to optimise production flows.Compressed air is a flexible and versatile working medium. Quite a number of works can not operate without the help of compressed air. And compressed air is worth its price. You only have to make sure to rigorously use the saving potentials hidden in the overall system.There are approximately 60,000 compressed air plants in Germany with an annual energy consumption of 14 billions of kWh. This corresponds to 5 % of the total industrial energy consumption (source: Fraunhofer Institut für System- und Innovationsforschung ISI [Fraunhofer Institute for Systems and Innovation Research ISI]). The immense saving potential is around 30 %.Air Audits: Saving through auditing.

Detailed examination at regular intervals is the first step to improve the energy efficiency of compressed air systems. The focus is on the exact air volume, safe quality, reliable FAD, and reasonably priced generation of compressed air. It is the objective of BOGE to evaluate all fields concerned including generation, and treatment of compressed air as well as process control. By evaluating all areas you can detect any possible source of defect, from production processes to be corrected to leakages to be remedied. Leakages tend to cause the highest energy costs, and can in most cases be stopped by simple immediate measures. Make sure to carry out regular inspections and eventual corrections, and the expected savings will be visible on the energy bills before long. BOGE recommends carrying out the following tests: Consumption test

- for consumption evaluationDew point control

- for long term quality assuranceVibration control

- for prevention of expensive idle operationLeakage test

- for effective cost reductionSound test

- for minimisation of sound levelOil check

- for fast and cost effective quality checkTAN check

- for determination of the compressor oil TAN value by means of a shake testFor an immediate response to your questions please email us at info (at) boge.com or phone us at +49 5206 601-0. It's the original that counts. From BOGE.

Screw compressors, piston compressors, compressed air dryers and the comprehensive accessories programme of BOGE are designed to meet the highest quality requirements. A detailed maintenance list will give information on repairs and the use of original BOGE parts and replacement of wear parts. And they exclusively originate from BOGE. If BOGE is written on it, BOGE is contained in it.Only the use of original BOGE parts guarantees proper functioning of your machines and equipment after repair or maintenance. Original BOGE spare and wear parts have the technological edge of the manufacturer and are subject to the strictest test criteria: optimum fitting accuracy, highest quality material, durability, and unlimited functionality. Use original BOGE spare parts to extend the service life of your installation and to increase its resale value.

Screw compressors, piston compressors, compressed air dryers and the comprehensive accessories programme of BOGE are designed to meet the highest quality requirements. A detailed maintenance list will give information on repairs and the use of original BOGE parts and replacement of wear parts. And they exclusively originate from BOGE. If BOGE is written on it, BOGE is contained in it.Only the use of original BOGE parts guarantees proper functioning of your machines and equipment after repair or maintenance. Original BOGE spare and wear parts have the technological edge of the manufacturer and are subject to the strictest test criteria: optimum fitting accuracy, highest quality material, durability, and unlimited functionality. Use original BOGE spare parts to extend the service life of your installation and to increase its resale value.Note: Preventive maintenance helps to avoid emergency repairs or operational downtimes. Original spare parts - fast, safe and easy from your BOGE spare parts shop.

BOGE supports the VDMA "Pro-Original" campaign. Clever packages: cairpacs from BOGE.

They're able to pack a punch.

The proven ready-to-use BOGE maintenance packages are available for C series and S series (up to the S100) compressors. Ordering a cairpac means saving up to 25 % compared to ordering individual spare parts.A single BOGE-cairpac contains everything that you need for proper servicing and maintenance. It couldn't be easier! cairpacs are carefully packed and contain the following items: cairpac 3000: oil filter, oil separator, intake air filter cartridge, wear and spare parts set for minimum pressure valve, wear and spare parts set for oil control unit, sealings Original spare parts - fast, safe and easy from your BOGE spare parts shop. High quality lubricants from BOGE. For high quality systems.

Compressor lubricants are subject to high requirements. All lubricants from BOGE are blended from top grade basic oils. Their viscosity meets the stringent requirements of BOGE compressed air systems. Lubricants from BOGE are formulated to ensure trouble-free operation of your compressor station - in the long run and with lasting effects. Our sales programme: FULL SYNTHETIC BOGE SYPREM S - the premium screw compressor coolant BOGE SYPREM P - especially made for piston compressors EFFECTIVE BOGE 3000plus - the standard special screw compressor coolant EFFICIENT COOLING BOGE 3000HTplus - for high ambient temperatures BIODEGRADABLE BOGE HighLub 6000 - with biodegradable residues FOOD & PHARMA BOGE FoodLub-H1 P - for the food and pharmaceutical industries for piston compressors BOGE FoodLub-H1 S - for the food and pharmaceutical industries for screw compressors Original spare parts - fast, safe and easy from your BOGE spare parts shop.