Boge Compressors

-

Refrigerant Dryers

Energy efficiency in drying air

Efficiency in every detail.

369_EN_Dryers.pdf

Technical data

DS series:

0,2 - 180 m3/min

7 - 6356 cfm

Max. operating pressure:

16 / 14 bar

235 / 203 psigThe DS series refrigerant dryers.REALISING THE FULL POTENTIAL When it comes to energy efficient compressed air drying, not only is the energy consumption of the dryer a key factor but the power consumption of the compressor is of even greater importance. Just a small decrease in pressure loss across the dryer means a reduction in generation pressure which in turn saves energy.

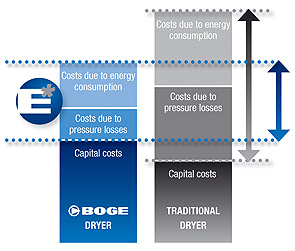

Due to the compact layout design coupled to the built in energy saving components the BOGE DS series dryers are able to operate with extremely low pressure differentials compared to traditional refrigerant dryers. And, don’t forget; each one bar reduction in generation pressure saves around six percent in energy consumption. The DS series dryers are therefore not only inherently energy effi cient but they will also reduce the energy consumption of the compressor itself. LOW PRESSURE LOSS

LOW PRESSURE LOSS

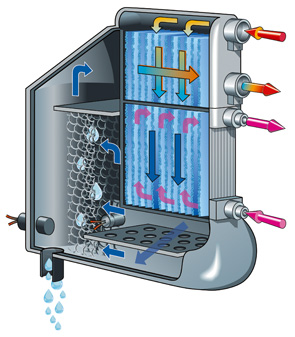

The DS series refrigerant dryers are extremely energy efficient. The patented design of the heat exchanger and its particularly generously dimensioned and optimal airflow not only ensure an energy efficient drying process but also extremely low pressure differentials which consequently reduce the power consumption of the compressor. This creates a larger savings potential than just the dryer alone. LOW POWER CONSUMPTION

LOW POWER CONSUMPTION

The DS series is equipped with an innovative control including an integrated energy saving function which ensures a particularly low power consumption of the dryer. It is also able to adapt the energy consumption to the actual prevailing operating conditions. Temperature fluctuations - due to seasonal variations and other factors - are measured by sensors and sent to the control system. The energy saving control unit serves to minimise the energy consumption and to reduce costs - at a constant pressure dew point. The BOGE efficiency edge: a total cost comparison shows that reduced pressure losses and low energy consumption ensure a rapid pay back period on the DS series dryers - a clear advantage for both the environment and your investment.

The BOGE efficiency edge: a total cost comparison shows that reduced pressure losses and low energy consumption ensure a rapid pay back period on the DS series dryers - a clear advantage for both the environment and your investment.DS 2 - DS 60

Refrigerant Dryers DS 2 - DS 60 Series

369_EN_Dryers.pdf

Flow capacity:

0,20 - 6,00 m3/min

7 - 212 cfm

Max. operating pressure:

16 bar, 235 psigThe most efficient method of drying compressed air: when compressed air is cooled near to freezing point, water and oil vapours create condensate. This method of drying is expensive to the end user as it uses energy and creates pressure losses. Because of its energy saving components, the DS series is capable of substantially reducing such costs over the entire lifetime of the compressed air system by combining savings potentials with maximum reliability.RELIABLE PRESSURE DEW POINT

Due to its generously dimensioned components, the DS series is able to ensure a reliable dew point along with a consistently high compressed air quality as well as a low pressure differential. The generation pressure can therefore be optimised. The DS series dryers are equipped with a pressure dew point indicator.LOWEST POSSIBLE PRESSURE LOSS

All DS series dryers are characterised by their extremely low pressure differential. This means that the generation pressure of upstream compressor can be optimised. Remember each one bar reduction in generation pressure saves around six percent in energy consumption - much more than with any other dryer systems.

INTELLIGENT DESIGN

All components are time proven and field tested. The intelligent layout of the robust heat exchanger package is engineered to guarantee energy saving operation. A removable canopy ensures easy access for routine inspections.ENVIRONMENTALLY FRIENDLY COOLANT

The R134a coolant does not have any ozone depleting characteristics. That, in conjunction with the use of recyclable materials and the in-built energy efficiency provides a true environmentally friendly product for the drying of compressed air.ENERGY EFFICIENT

The DS dryers have exceptionally low pressure differentials across the range. Remember each one bar reduction in generation pressure saves around six percent in energy consumption. The DS series therefore realises savings where potentials are highest and at the same time develops further saving potentials that traditional dryers cannot reach.DS 75 - DS 1800

Refrigerant Dryers DS 75 - DS 1800 Series

369_EN_Dryers.pdf

Flow capacity:

7,58 - 180 m3/min

268 - 6356 cfm

Max. operating pressure:

14 bar, 203 psigExtremely energy efficient compressed air drying: Owing to its efficient control, this range ensures absolutely economical compressed air drying. The generously dimensioned components are designed to ensure extremely low pressure differentials and to optimise pressure generation. Remember each one bar reduction in generation pressure saves around six percent in energy consumption.RELIABLE PRESSURE DEW POINT

From the DS 120 model, the pressure dew point is displayed on the control panel. A reliable dew point is essential for a consistently high compressed air quality and a low pressure differential. The generation pressure can therefore be optimised.INTEGRATED CONDENSATE DRAIN

All models come standard with an electronic level controlled condensate drain. Both the DS 75 and DS 95 are equipped with a Bekomat 32. From the DS 120 model, a condensate drain is integral to the heat exchanger and linked to the dryer control in order to save space - for even more safety and efficiency.INTELLIGENT DESIGN

All components are time proven and field tested. The intelligent layout of the robust heat exchanger package is engineered to guarantee energy saving operation. A removable canopy ensures easy access for routine inspections.ENVIRONMENTALLY FRIENDLY COOLANT

The R407c coolant does not have any ozone depleting characteristics. That, in conjunction with the use of recyclable materials and the in-built energy efficiency provides a true environmentally friendly product for the drying of compressed air.ENERGY EFFICIENT

The DS dryers have exceptionally low pressure differentials across the range. Remember each one bar reduction in generation pressure saves around six percent in energy consumption. The DS series therefore realises savings where potentials are highest and at the same time develops further saving potentials that traditional dryers cannot reach.DH 4 - DH 630

369_IT_Dryers.pdf The efficient way to get dry compressed air - Refrigerant compressed air dryers DH 4 to DH 630.

Flow capacity:

0,42 - 63 m3/min

15 - 2225 cfm

Max. operating pressure:

50 bar, 725 psigIf you are looking for an effective way to generate dry compressed air, the BOGE DH refrigerant compressed air dryers are the right choice every time. They are characterized by their low energy consumption and extraordinarily low pressure losses. This means the two largest cost drivers in compression air drying can be systematically eliminated – while at the same time retaining absolutely reliable and safe operation!Features of the DH models:Reliable pressure dew point. • Generously dimensioned components

• Reliable pressure dew point

• Consistently high compressed air quality

• With pressure dew point indicatorIntelligent design. • Proven and field tested components

• Easily accessible interior due to removable cover

• Efficient heat exchanger module guarantees energy-saving operationEnvironmentally friendly operation. • R 134a/R 407c without ozone depleting potential

• Recyclable materials

• High energy efficiency

• Maximum conservation of resourcesSystematic efficiency. • Extraordinarily low pressure loss, no expensive higher compression required

• Less overcompression necessary in the compressor as a result

• 6% savings on compressor energy costs for every bar of overcompression savedExtensive equipment. • Illuminated switch

• Heat exchanger with demister

• Power plug up to DH 90

• Optional: standard bypass line and special voltagesBOGE Refrigerant compressed air dryers DH 4 to 630: the consistent way to save energy! Membrane Dryers

DM...V

369_IT_Dryers.pdf BOGE-Membrane Dryer, DM...V Series

Flow capacity:

125 - 2730 l/min

4 - 96 cfm

Max. operating pressure:

7 - 15 bar

100 - 220 psigMembrane Dryers are used to reduce the pressure dewpoint.

Preferably to be installed between compressor and compressed air receiver.Pressure dewpoint reduced (Δt) between 20°C and 55°C • a multitude of applications are suitable for the Membrane Dryer Pre-filter with condensate drain supplied standard • technically oil-free compressed air No moving parts, no motors • electrical energy savings CFC free • significant contribution to protecting the ozone layer and the environment Water separation by means of pre-filtration • dependable operation of membrane dryer Compact unit • easy to install, small space required • minimum installation costs Adsorption Dryers

DA(C)Z

369_EN_Dryers.pdf BOGE Adsorption Dryers

DAZ

Flow capacity:

8 - 6100 m3/h

4 - 3587 cfm

Max. operating pressure:

10 and 16 bar

150 and 230 psig

DACZ

Flow capacity:

8 - 950 m3/h

4 - 559 cfm

Max. operating pressure:

10 and 16 bar

150 and 230 psigDAZ series

heatless with pre- and after filtersHeatless adsorption dryers with pressure dewpoints to -70 °C are suitable when D series refrigerant dryers with pressure dewpoints of + 3 to +7 °C will not meet the requirement. Before drying, the standard BOGE FP series micro-filter removes any solid and liquid impurities up to 0.01 mm from the compressed air supply. In the adsorption dryer, the desiccant material adsorbs moisture from the air, resulting in clean, dry compressed air. Pressure dewpoints to -40 °C can be achieved with the standard model. In parallel with moisture adsorption, regeneration takes place in a second vessel. With type DAZ heatless adsorption dryers, compressed air which has already been dried is used to regenerate the desiccant. BOGE DACZ series Treatment System DAV

369_EN_Dryers.pdf BOGE Adsorption Dryers

Flow capacity:

420 - 14500 m3/h

247 - 8526 cfm

Max. operating pressure:

10 bar, 150 psigDAV Series

Externally heated regeneration with vacuum drying, complete with pre-filter and after-filter

Vacuum regenerated adsorption drying is the energy efficient solution for higher volumes of compressed air. Dewpoints to -70°C are possible! Before drying, the standard BOGE FP series micro-filter removes any solid and liquid impurities up to 0.01 mm from the compressed air supply. Before entering the dryer, a BOGE ‘F’ series micro-filter removes solids and impurities from the compressed air to 0.01 mg/m3. In the drying tower, the desiccant media removes moisture from the air to a dewpoint of -40°C (standard models). The parallel tower regenerates the wet desiccant bed. First it de-pressurises to atmosphere, simultaneously the vacuum pump begins to draw ambient air, that is pre-heated on entry, through the wet desiccant to complete the regeneration process. BOGE D A

369_EN_Dryers.pdf BOGE Adsorption Dryer D A

Flow capacity:

0,09 - 5,51 m3/min

3 - 195 cfm

Max. operating pressure:

16 bar

232 psigOwing to its safe and efficient BOGE design principle, BOGE adsorption dryers are able to reliably produce dry quality class 2 compressed air according to DIN ISO 8573.1 and are ideally suited for medical technology or the food industry.We recommend using the optional pressure dew point control serving to reduce the regeneration air volume in dependence of temperature, pressure and FAD and to reduce energy costs at the same time.