Boge Compressors

-

Compressor Controls

Brochure305_EN_Controls.pdf BASIC / FOCUS

334_EN_Leakage-Monitor.pdf

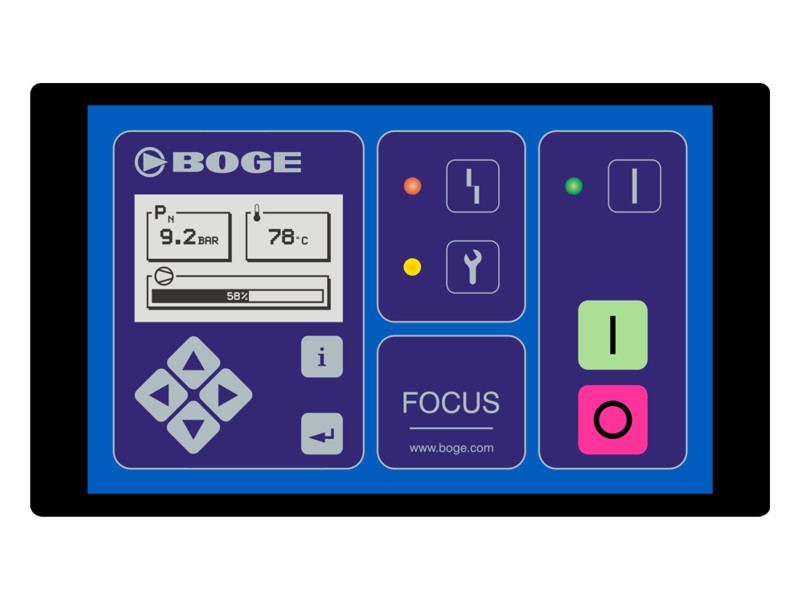

Compressor controls BASIC / FOCUS

THE ORIGINAL VERSION: BASIC •5 parameters in main display •In situ software update possible •Code programmable •Automatic antifreeze operation •Auto restart •Potential-free contacts for messages (retrofittable)

THE VERSATILE VERSION: FOCUS

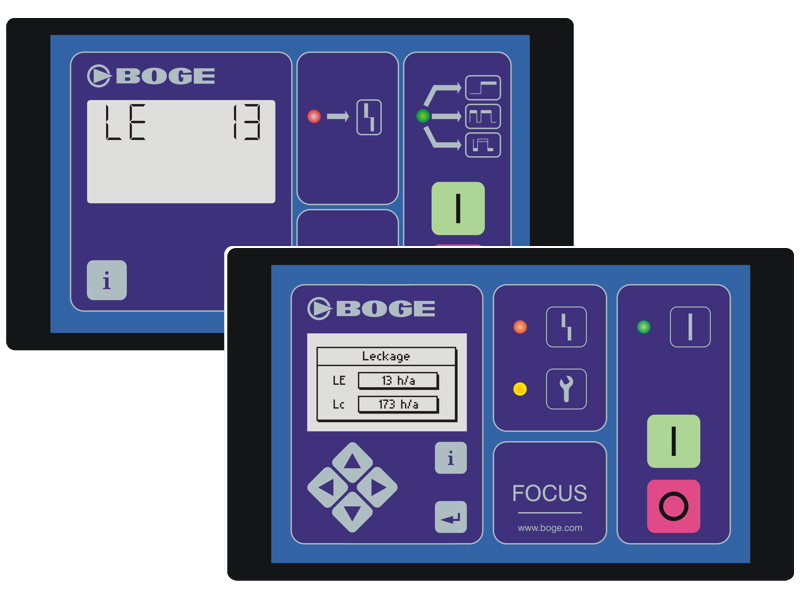

Additional functionality:•Remote On/Off facility (e.g. remote control panel) •Local/remote control via key switch •Compressed air processing control •System pressure sensor •Ring memory (last 30 messages) •Compressor efficiency display •Potential free contacts for error / maintenance messages and operating state •Base load switch control for up to 4 compressors via RS 485 interface as standard •Modular add-ons BOGE Leakage Monitor Cuts costs in compressed air production Manage and save your costs by simple use of the BOGE leakage monitor. Leakages tend to occur in almost every compressed air network. The BOGE leakage monitor serves to detect and help you successfully remove such leakages easily. Due to this particular BOGE developed option, compressed air losses are measured and shown in the display of the compressor control. This will allow you to plan a repair programme to eliminate these leakages in order to cut energy costs. By the way: In accordance with the BOGE efficiency principle, all new BOGE BASIC and FOCUS controls are equipped with the BOGE leakage monitor as standard. Advantages of the BOGE Leakage Monitor: •dependable, automatic measurement automatic detection of the amount of leakage during compressor motor turn-off times. •free-of-charge, retrofit leakage monitoring easy to install software update for existing BOGE compressors at no charge. •convenient optimisation of compressed air production eliminate compressed air losses and save costs with the BOGE leakage monitor PRIME

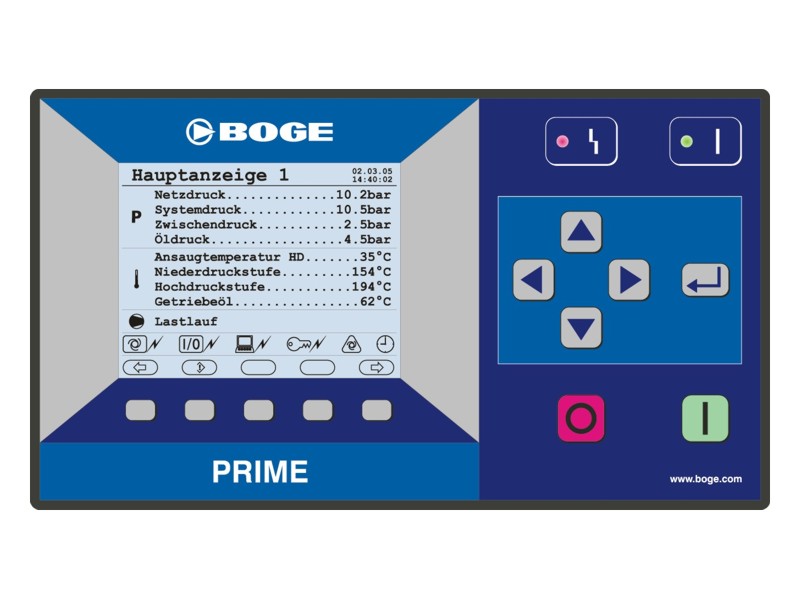

PRIME - the state-of-the-art highly efficient BOGE control

PRIME is the state-of-the-art highly efficient BOGE control. A large-scale, back-lit LC display with clear text output shows the fault and maintenance messages, operating modes and all operating parameters clearly arranged in three main displays. Volume flow and pressure characteristics are graphically displayed and freely scalable. Due to the modular design optional displays - for example pressure dew point - can be easily added. The PRIME control has an integrated real-time clock and a switch clock function enabling it to evenly control external equipment. Communication is achieved via RS 485 interfaces or potential-free signalling contacts.