Boge Compressors

-

Filteration

CLEARPOINT®

Better performance, long service lives, low costs: CLEARPOINT

The CLEARPOINT filter technology guarantees low operating costs, long service lives, outstanding process reliability and the safe filtration of aerosols, oil and dust. The comprehensive range of products covers a performance spectrum between 35 and 34,680 m³/h (at 7 bar) and includes threaded and flanged filters, as well as high-pressure filters up to 500 bar.

The CLEARPOINT filter technology guarantees low operating costs, long service lives, outstanding process reliability and the safe filtration of aerosols, oil and dust. The comprehensive range of products covers a performance spectrum between 35 and 34,680 m³/h (at 7 bar) and includes threaded and flanged filters, as well as high-pressure filters up to 500 bar.

Through the innovative 3E filter elements (3E = Energy Efficient Element) and a flow-optimised, corrosion-protected housing construction, CLEARPOINT offers safe and reliable filtration and qualitatively better compressed air at significantly reduced operating costs.Convincing in all details: the 3E filter elements

With a unique fibre structure and a new manufacturing technology, the filter elements of the CLEARPOINT series set new standards in compressed-air filtration.

With a unique fibre structure and a new manufacturing technology, the filter elements of the CLEARPOINT series set new standards in compressed-air filtration.

Material and method optimised

For the 3E filter elements, binding agents are not used at all. For the new medium, micro-fine borosilicate fibres and polyester fibres are thermally fused. In this respect, a high number of fibres with a smaller diameter ensure a finer fibre structure. The material thus boasts a separation surface which is four times larger than conventional filter media, and a larger cavity volume.Filtering with 3E: extra efficient

The long-term-stable composite of the fibres guarantees a high separation rate over the entire depth of the filter bed and sustainably supports the dirt absorption capacity. In addition, this structure ensures perfect fluid mechanics and thus additionally reduces the pressure difference. The results are significant energy savings of up to 40% at maximum filtration performance.CLEARPOINT Advantages:

• Reduction of the operating costs, enhanced profitability during operation

• Safe filtration of liquids such as water or oils, of dusts, gases or aerosols

• Longer service lives and a qualitatively better compressed air

• Increase in the machine runtime

• Improved product quality through the reduction of rejects

• Reduced preventive maintenance increases productivity

• Better working and production conditionsThe CLEARPOINT filter elements: the 3E performance plus

• Performance-optimised: volume flow higher by up to 30%

• Energy-optimised pressure difference

I• proved separation rate

• High dirt absorption capacity

• No intrinsic particle release

• Low flow resistance through an optimised interior and exterior stainless steel supporting cylinder

• Tested and validated in accordance with ISO 12500High-Pressure Filters

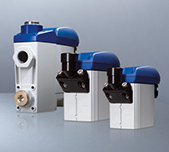

Innovative with Service Unit

BEKO TECHNOLOGIES transforms its international experience of more than 30 years into a new BEKOMAT generation. With innovations which offer unprecedented advantages to the users.

BEKO TECHNOLOGIES transforms its international experience of more than 30 years into a new BEKOMAT generation. With innovations which offer unprecedented advantages to the users.

BEKOMAT 31U/32U/33U and 33UCO combine new solutions and significant advances in technology. Even more reliability, fast and smooth installation, maintenance with minimum time requirements BEKO TECHNOLOGIES achieves these targets through an innovative construction which consists of only two or three units with quick release connectors. This means the new BEKOMAT can be serviced in seconds, without decoupling from the pipework system.The devices of this new generation are made up of only two modules: a service unit com- prising the corrosion-resistant aluminium housing together with all maintenance-relevant components, and an electronic control and sensor unit which is installed only once. Both modules are coupled via a practical snap connection.This design makes it possible to replace all parts subject to wear or requiring maintenance in one go: the old service unit is simply and quickly removed and a new, works-tested unit is fitted instead. The separation and connection of the two modules requires no tools - it's all done in next to no time.Sometimes, an idea changes everything.

Thirty years ago the first BEKOMAT® created a new market: automatic condensate drainage with no energy loss. Since then BEKO TECHNOLOGIES has continued to set the standards for effi cient and process-safe condensate drainage. The upgrade versions of 31 | 32 | 33 BEKOMAT®are the climax of a development that has continuously adapted a proven concept to match changing customer requirements with state-of- the-art technology. The latest generation connects proven safety with intelligent design and trend-setting ease-of-maintenance: the device monitors its own service requirements and indicates when maintenance is required. Performance thereby becomes still more efficient and cost-effective.

Thirty years ago the first BEKOMAT® created a new market: automatic condensate drainage with no energy loss. Since then BEKO TECHNOLOGIES has continued to set the standards for effi cient and process-safe condensate drainage. The upgrade versions of 31 | 32 | 33 BEKOMAT®are the climax of a development that has continuously adapted a proven concept to match changing customer requirements with state-of- the-art technology. The latest generation connects proven safety with intelligent design and trend-setting ease-of-maintenance: the device monitors its own service requirements and indicates when maintenance is required. Performance thereby becomes still more efficient and cost-effective.The advantages of BEKOMAT 31|32|33 Update at a glance: • The universal power supply dramatically reduces stock requirements

• Moisture protection rating increased to IP67

• Flashing LED indicates service requirement

• Full compatibility: the new service unit retrofits to all previous versions

• Suitable for a temperature range from +1°C to +60°C. Optional: +70°CCLEARPOINT® V

Multistage compressors

If the condensate from the intercoolers is not reliably drained in multistage compressors, it will reach the next compressor stage. BEKOMAT LA/LP prevents damage through “drop attacks”, condensate buildup and water hammers.

Vacuum

Especially employable for condensate drainage in vacuum or pressureless systems at operating pressures from 0.1 to 1.8 bar (abs.).Hazardous areas

Special units are also available for the application in hazardous areas (II 2G EEX ib IIB T4 / explosion class II B, temperature class T4) where ignition sources need to be prevented. Permissible fluids are ethane, methane, town gas, diesel fuel, ethylene, propane, fuel oil and compressor oil. Stainless-steel versions

For the drainage of particularly aggressive condensates.